How Specialist Commercial Refrigerator Repair Can Boost Your Organization Effectiveness

Wiki Article

Maximizing Efficiency: Commercial Refrigeration Fixing Techniques for Cost-Effective Solutions

Assessing Refrigeration System Performance

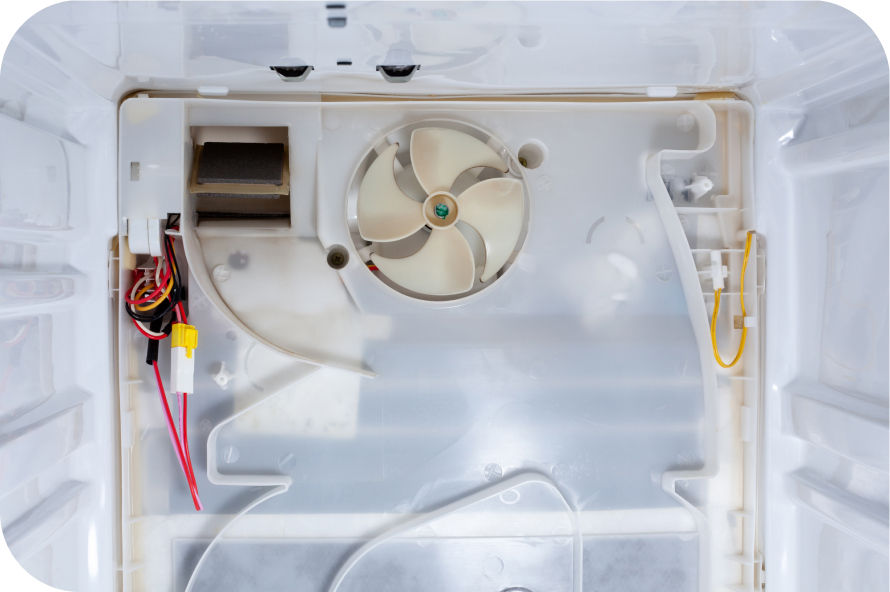

To efficiently evaluate the performance of an industrial refrigeration system, it is important to conduct detailed analyses of its operational specifications and vital components. The initial action in analyzing system performance is analyzing the performance of the compressor. The compressor plays an essential role in keeping the preferred temperature level within the refrigeration device. Issues with the compressor can cause insufficient cooling, temperature level variations, and increased energy usage. Performing regular inspections and performance tests on the compressor can help recognize potential problems early on and avoid pricey breakdowns.Additionally, assessing the condenser and evaporator coils is paramount. Dirty or blocked coils can considerably impact the system's performance by impeding warmth transfer procedures. Cleaning up the coils frequently and making sure appropriate airflow around them can optimize the system's air conditioning capability and reduce power consumption. Checking refrigerant degrees and pressures is additionally crucial in evaluating system efficiency. Low refrigerant degrees or uncommon pressures can indicate leaks or malfunctioning parts that need prompt attention to stop system failings and costly fixings. By methodically evaluating these vital elements and operational criteria, companies can guarantee their commercial refrigeration systems operate at peak performance degrees, reducing downtime and taking full advantage of energy efficiency.

Carrying Out Preventative Maintenance Measures

Assessing the performance of an industrial refrigeration system supplies useful understandings that can notify the execution of preventative maintenance steps important for sustaining ideal performance and long life. Preventative upkeep is a positive strategy targeted at identifying and addressing prospective issues prior to they rise into pricey issues that interrupt procedures. By establishing a routine upkeep routine, refrigeration systems can run effectively, decreasing power consumption and reducing the danger of unexpected breakdowns. Key preventative upkeep procedures include evaluating and cleansing condenser coils, inspecting cooling agent levels, ensuring appropriate airflow, and adjusting temperature level controls. Additionally, keeping an eye on temperature and moisture levels, checking door seals, and dealing with any kind of uncommon sounds or odors quickly are vital action in preventative maintenance. Applying these procedures not only expands the life-span of the tools yet additionally enhances food safety and security by preserving regular storage space temperatures. Eventually, purchasing preventative upkeep procedures is an affordable approach that helps businesses avoid pricey repair services and downtime, ensuring constant and reliable refrigeration system performance.Identifying Common Refrigeration Issues

One of the key have a peek here facets in keeping industrial refrigeration systems is quickly determining typical concerns that may develop throughout their operation. Additionally, damaged gaskets on doors, resulting in air leakages, can trigger the refrigeration system to function tougher to keep the wanted temperature level. By without delay identifying and addressing these usual refrigeration problems, organizations can make sure the effective operation of their systems and minimize expensive repairs.Utilizing Energy-Efficient Repair Service Techniques

When thinking about commercial refrigeration repair, executing energy-efficient techniques is paramount to optimizing the system's performance and reducing functional costs. One of the key approaches in accomplishing power performance is making sure that the refrigeration system is properly kept. Regular upkeep, such as cleansing condenser coils, looking for cooling agent leaks, and adjusting temperature level settings, can substantially enhance energy performance.An additional energy-efficient repair work method is updating to high-efficiency components - commercial refrigeration repair. By replacing older, less effective parts with energy-efficient options, such as ECM fan electric motors or LED illumination, companies can minimize power consumption and reduced energy prices. Additionally, setting up programmable thermostats and power management systems can help manage temperatures much more efficiently, stopping unnecessary energy usage

Moreover, optimizing the system's insulation and sealing any kind of leakages can also contribute to power financial savings. Correct insulation aids preserve regular temperature levels within the refrigeration system, decreasing the work on the system and enhancing general effectiveness. By including these energy-efficient repair methods, organizations can not just minimize their ecological effect yet likewise attain long-lasting cost savings.

Optimizing Refrigeration System Life Expectancy

To ensure the long life and ideal efficiency of industrial refrigeration systems, keeping energy-efficient repair work methods is crucial, with a focus now changing in the direction of making the most of the refrigeration system life-span. Maximizing the life-span of a refrigeration system involves aggressive upkeep, timely fixings, and adherence to supplier guidelines. Regular assessments to identify prospective concerns before they intensify can substantially expand the system's useful site lifespan (commercial refrigeration repair). Executing a preventive upkeep routine that consists of jobs such as cleaning up coils, inspecting refrigerant degrees, and examining insulation can aid recognize problems early on and avoid pricey breakdowns.Furthermore, informing staff on appropriate system procedure and upkeep methods can add to the durability of the tools. Educating workers to report any uncommon audios, leakages, or changes in performance can aid in capturing troubles in their initial phases. In addition, purchasing top notch parts and parts throughout repair work and replacements can enhance the longevity of the refrigeration system. By prioritizing aggressive upkeep and utilizing top quality components, companies can enhance the lifespan of their industrial refrigeration systems, ultimately reducing downtime and operational costs.

Final Thought

Finally, by routinely evaluating refrigeration system efficiency, executing preventative maintenance steps, recognizing common refrigeration concerns, making use of energy-efficient fixing techniques, and enhancing the system's life expectancy, organizations can optimize efficiency and reduce prices connected with commercial refrigeration repair. These affordable remedies aid to make certain that refrigeration systems operate at peak efficiency, ultimately bring about boosted productivity and profitability for organizations in the future.

When taking into consideration business refrigeration repair service, carrying out energy-efficient strategies is critical to optimizing the system's efficiency and decreasing functional prices.To make sure the longevity and get more optimum performance of commercial refrigeration systems, maintaining energy-efficient fixing practices is necessary, with a focus currently moving towards taking full advantage of the refrigeration system life-span. Optimizing the life expectancy of a refrigeration system includes positive upkeep, timely repairs, and adherence to maker standards.

Report this wiki page